- +91 9823101312

- +91 9967248672

- sales@rmbknovatech.com

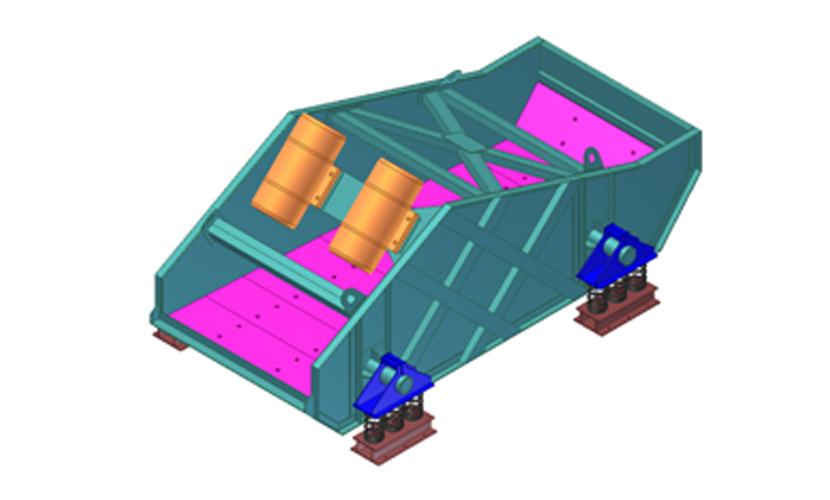

Dewatering Screen

Dewatering Screen

Dewatering Screen

Type: Screening equipment remove water from washed manufactured sand or ore.

Feed Size: :≤5mm

Capacity: 25-200t/h

Materials: Manufactured Washed sand or fine ore.

Applications: Mining, metallurgy, construction, highway, railroad etc.

Overview

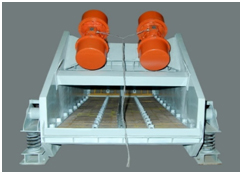

RMB KNOVATECH high-frequency Linear motion Vibrating screen to remove up to 50 percent of the water from washed sand and ore while maintaining maximum production no matter how wet the material is. It utilizes two vibrators that initiate a linear motion, driving particles in an uphill, downhill or horizontal direction – so water is strained down through the sand bed and below the screen deck.

Features

1. Frame : The vibrating frame has been specially designed to ensure maximum ruggedness and rigidity.Simple construction allows complete dismantling.

- Two side plates of heavy-duty design.

- Deck frames bolted to the side plates with high carbon high tensile bolts & consists of cross –members & deck bars.

- Dewatering Screens utilize a urethane deck with a 500micron aperture that allows the user to dewater a broad range of particle sizes. The deck can handle up to 14 inches of material depth, making use of the bottom thin layer of material as a secondary “screen,” allowing the deck to preserve fines smaller than 200 meshes.

2. Easy Coil – Spring Replacement:

- Modular pivoted spring mounting assembly for easy replacement and two-degree screen box inclination change.

Technology advantages :

- Sharp Accurate Sizing : Three factors guarantee the efficiency of the linear motion dewatering screen

- Stroke Adjustability

- Uniformity of Stroke

- Inclination adjustability

- High Output:

- Every square meter of the Screen is “alive “for highest capacity.

- Uniform motion throughout produces an accurately – sized product.

- Adjustable Stroke:

- Dewatering SCREEN are supplied with pre – set stroke as required by specific service applications. If a change in operating Conditions is required in the Field, the stroke is adjusted easily by change of setting of unbalance mass in electromechanical vibrator.

- Simple Maintenance:

- Screen cloth replacement easy and simple.

- All permanent connections are welded and maintenance – free.

- All bolted connection are with high carbon high tensile bolts.

- Modular construction.

Working Principle

The oscillating motion of the Feeder is imparted by the unbalance masses mounted on the extended shaft of the two Motor rotating at the same speed but in opposite direction. These motors are placed symmetrically about a line at right angle to the frame. As the resultant force due to unbalance masses passes through this line, it is called drive line. The total displacement in either direction is called “stroke” As it may be observed that at any instant of 360 rotation of the motors, individual motors are producing forces with components along the drive line and also at right angle to it. The forces at right angle to the drive line produced, are at opposite directions and cancel each other, leaving the forces only in the direction of the drive line.

Dewatering Screens have urethane decks, which resist wear and provide long life. They contain water dividers that divert material over the region where water passes through the screen, while 500-micron openings allow water to pass freely through – holding back material on the top side of the deck. When dewatering finer material, the lower layer of sand acts as a secondary filter that retains 99 percent of the material with the product, while only one percent goes to waste. On average, a concrete or masonry sand product achieves a final water-to material ratio of 1:10.

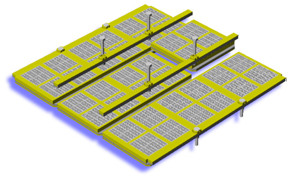

Technical Data : RMB Knovatech Single Deck Dewatering Screen

| Vibration Type | Linear | ||

|---|---|---|---|

| Vibrator Type | Electromechanical unbalance motor,415 V,50 Hz,6 Pole,1000 RPM IP 65 | ||

| Deck Type | Flat modular urethane Deck | ||

| Aperture Size | 0.2 mmx 11 mm | ||

| Bed Angle | Adjustable -5 deg to +5 deg | ||

| Model | KDS120/240-1D | KDS 150/360-1A | KDS 180/450-1A |

| Deck Width | 1200 mm | 1500 mm | 1800 mm |

| Deck Length | 2400 mm | 3600 mm | 4500 mm |

| Bed Area in Sq M | 2.88 | 5.4 | 7.8 |

| Screen Weight In Kg | 2400 | 3400 | 4400 |

| Unbalance Motor | 2.2 kWx1000 RPMx2 Nos | 3.2 kWx1000 RPMx2 Nos | 4.3 kWx1000 RPMx2 Nos |

Note : The capacity per hour is consider on the basis of bulk density with 1.6x10³kg/m³. Capacities are relative to physical character and type of feeding, feeding size and composition and so on

Download Brochure