- +91 9823101312

- +91 9967248672

- sales@rmbknovatech.com

Grizzly Feeder

Grizzly Feeder

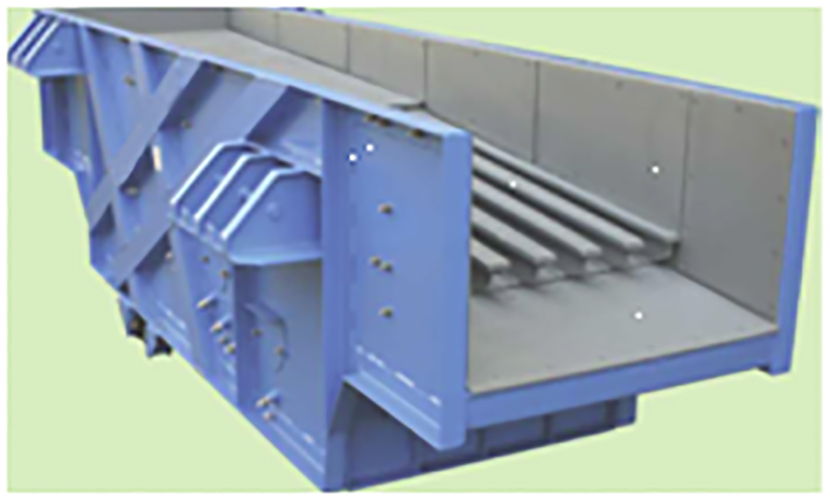

KGF Series Vibrating Grizzly Feeder

Type: Control Feeding and scalping equipment

Feed Size: 450mm-1000mm

Mode of Vibration: Linear Motion with Electromechanical unbalance Motor

Capacity: 50-600 TPH

Materials: Aggregate (River stone, gravel, granite, basalt, mineral, quartz, diabase), Iron ore, copper ore, cement, artificial sand, fluorite, limestone, slag, etc.

Applications: Mining, metallurgy, construction, highway, railroad, water conservancy, etc.

Overview

KGF series vibrating Grizzly feeder uses vibrating motor to produce vibration force. It is used to feed materials into primary crusher homogeneously. Because of the bar-shaped screen, it can increase primary crushing capacity through filter out smaller sizeparticle in raw materials. Compare to other conveying means vibrating grizzly feeders with unbalance motors have low energy consumption. Trough is provided with wear resistant liner. Unbalance Motors provided with the feeder are robust, reliable in operation have a high loading capacity and with least maintenance. They have generously dimensioned special heavy vibration proof winding, totally enclosed with IP-55 degree of protection and are suitable for weather proof outdoor.

Features and technology advantages

RMB Knovatech Vibrating Grizzly Feeder reduces maintenance cost and lower capital expenditure by eliminating Feeder and Grizzly.

- Scalping and feeding in a single unit.

- Grizzly Feeder components include:

- Vibrating Body

- Conveying Trough with wear liner

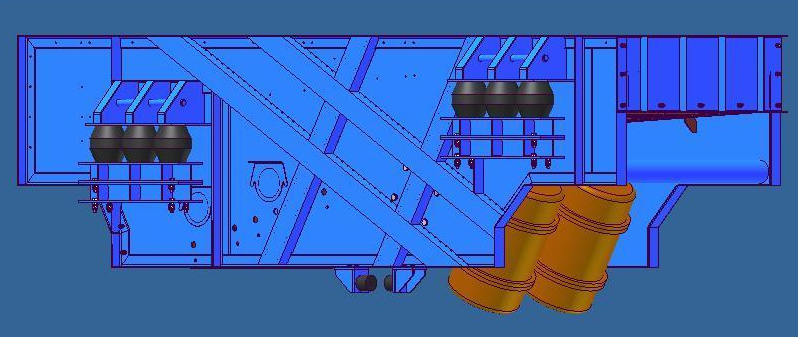

- Electro-mechanical Vibrating Motor

- Rubber Spring Units for better isolation

- Heavy duty Structures

- Feeding Mouth

- Grizzly Bar wear resistant

- Heavy duty Wire Mesh

- Tapered Opening of grizzly bar to prevent material plugged between the bars

- A Grizzly Feeder performs following important functions :

- Takes the shock of heavy dumped load without affecting the superstructure

- Regulate feed rate to the plant

- The Grizzly section separates material for product sizing and remove unwanted fines and bypasses smaller material around the crusher

Working principle of Grizzly Feeder

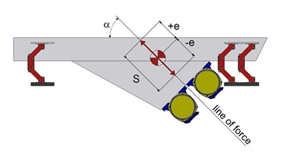

The oscillating motion of the Feeder is imparted by the unbalance masses mounted on the extended shaft of the two Motor rotating at the same speed but in opposite direction. These motors are placed symmetrically about a line at right angle to the frame. As the resultant force due to unbalance masses passes through this line, it is called drive line. The total displacement in either direction is called “stroke” As it may be observed that at any instant of 360 rotation of the motors, individual motors are producing forces with components along the drive line and also at right angle to it. The forces at right angle to the drive line produced, are at opposite directions and cancel each other, leaving the forces only in the direction of the drive line.

Technical Data : Model and Detail Specification of Grizzly Feeder

| Model | Width x Length (mm) | Capacity (tph)* | Unbalance Motor Kw x rpm x qty | Vibrating Type | Acceleration (g force) | App. Wt.(kg) | |

|---|---|---|---|---|---|---|---|

| Vibrating | Static | ||||||

| KGF 80/350-2D | 800 x 1500 | 50-100 | 2.5 kWx1000 RPM x 2 Nos. | Linear | 3.0<G<5.0 | 2850 | 800 |

| KGF 100/400-2D | 1000 x 4000 | 100-150 | 3.8 kWx1000 RPM x 2 Nos. | Linear | 3.0<G<5.0 | 3650 | 1000 |

| KGF 120/450-2D | 1200 x 4500 | 150-250 | 5.5 kWx1000 RPM X 2 Nos. | Linear | 3.0<G<5.0 | 4450 | 1200 |

| KGF 140/550-2D | 1400 x 5500 | 250-350 | 6.2 kWx1000 RPM X 2 Nos. | Linear | 3.0<G<5.0 | 6050 | 1500 |

Note : The capacity per hour is consider onthe basis of bulk density with 1.6x10³kg/m³.Capacities are relative to physical character and type of feeding, feeding size and composition and so on

Download Brochure